Click here to see new mini 3 - 5 layer coex with oscillating nip

Laboratory Co-Extrusion Systems and Controls

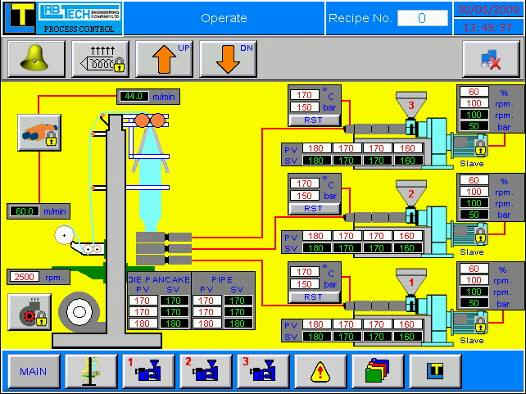

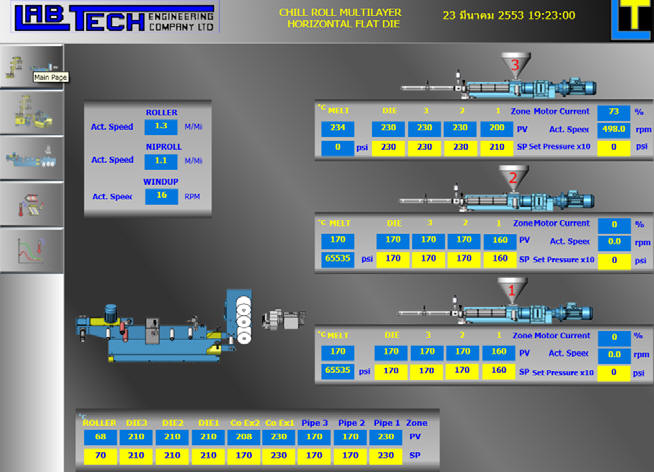

The computer co-ex extruder controls can be incorporated on a central control panel, for instance when used for a co-extrusion line. Picture to the right shows the panel for a 3-layer co-ex film line and to the right on the screen are the three extruders shown. Here all parameters on extruders and downstream film blowing unit are controlled by touching respectively the symbol shown at the bottom of the screen.

5 Layer, (3)- 12.5mm Extruders with LCR-175 Co-Ex Chill Roll Cast Film Line with PC Data Acquisition Program

The Conical Extruder screws are easily removed from rear of gearbox with out disassembly of machine.

The extruder screw has a diameter of 12.5

mm and length 30D. The diameter of

the in-feed section of the screw has been increased to 20 mm in order to

allow

the feeding of regular sized pellets,

PC Windows Based Cast Film line Data Acquisition Software Screen Shot

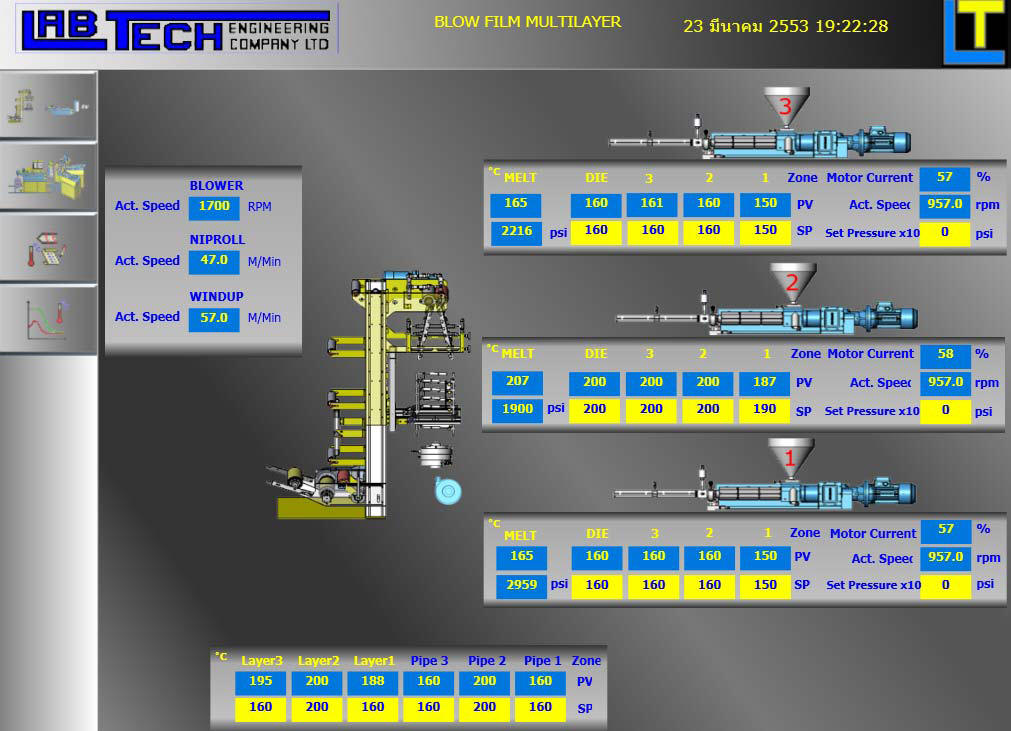

LF-250 Blown Film 3 layer Co-Extrusion line with (3) 12.5mm, 30:1 extruders, with PC Windows Data Acquisition System

PC Windows Based Blown Film line Data Acquisition Software Screen Shot

LBCR-350 Co-Ex Cast Film Line with (3) 25mm 30:1 Extruders

Horizontal Roll Stack set up for PET-G

|

Load Cell Windup Tension Control System |

|

3 Layer Co-Ex Blown Film with Gravimetric Layer Thickness Control and Load Cell Tension Wind Up Control |

|

|

Scientific Co-Extrusion Blown Film Systems

For Quality Control, Product Development

Blown film co-ex lines are

available with up to 9 layers![]()

7 layer co-ex with 7 extruders (25mm - 45mm) Shown:

Integrated central computer control or analog control.

Available 12.5mm, 20mm, 25mm, 30mm, and 45mm single screw extruders, vented or non vented barrels (25mm & up)

Optional Oscillating haul off is also available.

Click here to see startup of 12.5mm coex blown film line

Scientific Co-Extrusion Cast Film and Sheet Systems

For Quality Control, Product Development

Cast film co-ex lines are available with up to 7 layers

Integrated central computer control or analog control.

Available 12.5mm, 20mm, 25mm, 30mm, and 45mm single screw extruders, vented or non vented barrels (25mm & up).

Click here to see cast line startup movie

U.S.A. to Metric CONVERSION CHART

| TO CONVERT TO MILLIMETERS: MULTIPLY INCHES X 25.4 |

| TO CONVERT TO INCHES: MULTIPLY MILLIMETERS X 0.03937* |

|

*FOR SLIGHTLY GREATER ACCURACY WHEN

CONVERTING TO INCHES: DIVIDE MILLIMETERS BY 25.4 |

| INCHES | METRIC | INCHES | METRIC | INCHES | METRIC | |||

| FRACTIONAL | DECIMAL | mm | FRACTIONAL | DECIMAL | mm | FRACTIONAL | DECIMAL | mm |

| . | 0.0039 | 0.1000 | . | 0.5512 | 14.0000 | . | 1.8898 | 48.0000 |

| . | 0.0079 | 0.2000 | 9/16 | 0.5625 | 14.2875 | . | 1.9291 | 49.0000 |

| . | 0.0118 | 0.3000 | . | 0.5709 | 14.5000 | . | 1.9685 | 50.0000 |

| 1/64 | 0.0156 | 0.3969 | 37/64 | 0.5781 | 14.6844 | 2 | 2.0000 | 50.8000 |

| . | 0.0157 | 0.4000 | . | 0.5906 | 15.0000 | . | 2.0079 | 51.0000 |

| . | 0.0197 | 0.5000 | 19/32 | 0.5938 | 15.0813 | . | 2.0472 | 52.0000 |

| . | 0.0236 | 0.6000 | 39/64 | 0.6094 | 15.4781 | . | 2.0866 | 53.0000 |

| . | 0.0276 | 0.7000 | . | 0.6102 | 15.5000 | . | 2.1260 | 54.0000 |

| 1/32 | 0.0313 | 0.7938 | 5/8 | 0.6250 | 15.8750 | . | 2.1654 | 55.0000 |

| . | 0.0315 | 0.8000 | . | 0.6299 | 16.0000 | . | 2.2047 | 56.0000 |

| . | 0.0354 | 0.9000 | 41/64 | 0.6406 | 16.2719 | . | 2.2441 | 57.0000 |

| . | 0.0394 | 1.0000 | . | 0.6496 | 16.5000 | 2 1/4 | 2.2500 | 57.1500 |

| . | 0.0433 | 1.1000 | 21/32 | 0.6563 | 16.6688 | . | 2.2835 | 58.0000 |

| 3/64 | 0.0469 | 1.1906 | . | 0.6693 | 17.0000 | . | 2.3228 | 59.0000 |

| . | 0.0472 | 1.2000 | 43/64 | 0.6719 | 17.0656 | . | 2.3622 | 60.0000 |

| . | 0.0512 | 1.3000 | 11/16 | 0.6875 | 17.4625 | . | 2.4016 | 61.0000 |

| . | 0.0551 | 1.4000 | . | 0.6890 | 17.5000 | . | 2.4409 | 62.0000 |

| . | 0.0591 | 1.5000 | 45/64 | 0.7031 | 17.8594 | . | 2.4803 | 63.0000 |

| 1/16 | 0.0625 | 1.5875 | . | 0.7087 | 18.0000 | 2 1/2 | 2.5000 | 63.5000 |

| . | 0.0630 | 1.6000 | 23/32 | 0.7188 | 18.2563 | . | 2.5197 | 64.0000 |

| . | 0.0669 | 1.7000 | . | 0.7283 | 18.5000 | . | 2.5591 | 65.0000 |

| . | 0.0709 | 1.8000 | 47/64 | 0.7344 | 18.6531 | . | 2.5984 | 66.0000 |

| . | 0.0748 | 1.9000 | . | 0.7480 | 19.0000 | . | 2.6378 | 67.0000 |

| 5/64 | 0.0781 | 1.9844 | 3/4 | 0.7500 | 19.0500 | . | 2.6772 | 68.0000 |

| . | 0.0787 | 2.0000 | 49/64 | 0.7656 | 19.4469 | . | 2.7165 | 69.0000 |

| . | 0.0827 | 2.1000 | . | 0.7677 | 19.5000 | 2 3/4 | 2.7500 | 69.8500 |

| . | 0.0866 | 2.2000 | 25/32 | 0.7813 | 19.8438 | . | 2.7559 | 70.0000 |

| . | 0.0906 | 2.3000 | . | 0.7874 | 20.0000 | . | 2.7953 | 71.0000 |

| 3/32 | 0.0938 | 2.3813 | 51/64 | 0.7969 | 20.2406 | . | 2.8346 | 72.0000 |

| . | 0.0945 | 2.4000 | . | 0.8071 | 20.5000 | . | 2.8740 | 73.0000 |

| . | 0.0984 | 2.5000 | 13/16 | 0.8125 | 20.6375 | . | 2.9134 | 74.0000 |

| 7/64 | 0.1094 | 2.7781 | . | 0.8268 | 21.0000 | . | 2.9528 | 75.0000 |

| . | 0.1181 | 3.0000 | 53/64 | 0.8281 | 21.0344 | . | 2.9921 | 76.0000 |

| 1/8 | 0.1250 | 3.1750 | 27/32 | 0.8438 | 21.4313 | 3 | 3.0000 | 76.2000 |

| . | 0.1378 | 3.5000 | . | 0.8465 | 21.5000 | . | 3.0315 | 77.0000 |

| 9/64 | 0.1406 | 3.5719 | 55/64 | 0.8594 | 21.8281 | . | 3.0709 | 78.0000 |

| 5/32 | 0.1563 | 3.9688 | . | 0.8661 | 22.0000 | . | 3.1102 | 79.0000 |

| . | 0.1575 | 4.0000 | 7/8 | 0.8750 | 22.2250 | . | 3.1496 | 80.0000 |

| 11/64 | 0.1719 | 4.3656 | . | 0.8858 | 22.5000 | . | 3.1890 | 81.0000 |

| . | 0.1772 | 4.5000 | 57/64 | 0.8906 | 22.6219 | . | 3.2283 | 82.0000 |

| 3/16 | 0.1875 | 4.7625 | . | 0.9055 | 23.0000 | . | 3.2677 | 83.0000 |

| . | 0.1969 | 5.0000 | 29/32 | 0.9063 | 23.0188 | . | 3.3071 | 84.0000 |

| 13/64 | 0.2031 | 5.1594 | 59/64 | 0.9219 | 23.4156 | . | 3.3465 | 85.0000 |

| . | 0.2165 | 5.5000 | . | 0.9252 | 23.5000 | . | 3.3858 | 86.0000 |

| 7/32 | 0.2188 | 5.5563 | 15/16 | 0.9375 | 23.8125 | . | 3.4252 | 87.0000 |

| 15/64 | 0.2344 | 5.9531 | . | 0.9449 | 24.0000 | . | 3.4646 | 88.0000 |

| . | 0.2362 | 6.0000 | 61/64 | 0.9531 | 24.2094 | 3 1/2 | 3.5000 | 88.9000 |

| 1/4 | 0.2500 | 6.3500 | . | 0.9646 | 24.5000 | . | 3.5039 | 89.0000 |

| . | 0.2559 | 6.5000 | 31/32 | 0.9688 | 24.6063 | . | 3.5433 | 90.0000 |

| 17/64 | 0.2656 | 6.7469 | . | 0.9843 | 25.0000 | . | 3.5827 | 91.0000 |

| . | 0.2756 | 7.0000 | 63/64 | 0.9844 | 25.0031 | . | 3.6220 | 92.0000 |

| 9/32 | 0.2813 | 7.1438 | 1 | 1.0000 | 25.4000 | . | 3.6614 | 93.0000 |

| . | 0.2953 | 7.5000 | . | 1.0039 | 25.5000 | . | 3.7008 | 94.0000 |

| 19/64 | 0.2969 | 7.5406 | . | 1.0236 | 26.0000 | . | 3.7402 | 95.0000 |

| 5/16 | 0.3125 | 7.9375 | . | 1.0433 | 26.5000 | . | 3.7795 | 96.0000 |

| . | 0.3150 | 8.0000 | . | 1.0630 | 27.0000 | . | 3.8189 | 97.0000 |

| 21/64 | 0.3281 | 8.3344 | . | 1.0827 | 27.5000 | . | 3.8583 | 98.0000 |

| . | 0.3346 | 8.5000 | . | 1.1024 | 28.0000 | . | 3.8976 | 99.0000 |

| 11/32 | 0.3438 | 8.7313 | . | 1.1220 | 28.5000 | . | 3.9370 | 100.0000 |

| . | 0.3543 | 9.0000 | . | 1.1417 | 29.0000 | 4 | 4.0000 | 101.6000 |

| 23/64 | 0.3594 | 9.1281 | . | 1.1614 | 29.5000 | . | 4.3307 | 110.0000 |

| . | 0.3740 | 9.5000 | . | 1.1811 | 30.0000 | 4 1/2 | 4.5000 | 114.3000 |

| 3/8 | 0.3750 | 9.5250 | . | 1.2205 | 31.0000 | . | 4.7244 | 120.0000 |

| 25/64 | 0.3906 | 9.9219 | 1 1/4 | 1.2500 | 31.7500 | 5 | 5.0000 | 127.0000 |

| . | 0.3937 | 10.0000 | . | 1.2598 | 32.0000 | . | 5.1181 | 130.0000 |

| 13/32 | 0.4063 | 10.3188 | . | 1.2992 | 33.0000 | . | 5.5118 | 140.0000 |

| . | 0.4134 | 10.5000 | . | 1.3386 | 34.0000 | . | 5.9055 | 150.0000 |

| 27/64 | 0.4219 | 10.7156 | . | 1.3780 | 35.0000 | 6 | 6.0000 | 152.4000 |

| . | 0.4331 | 11.0000 | . | 1.4173 | 36.0000 | . | 6.2992 | 160.0000 |

| 7/16 | 0.4375 | 11.1125 | . | 1.4567 | 37.0000 | . | 6.6929 | 170.0000 |

| . | 0.4528 | 11.5000 | . | 1.4961 | 38.0000 | . | 7.0866 | 180.0000 |

| 29/64 | 0.4531 | 11.5094 | 1 1/2 | 1.5000 | 38.1000 | . | 7.4803 | 190.0000 |

| 15/32 | 0.4688 | 11.9063 | . | 1.5354 | 39.0000 | . | 7.8740 | 200.0000 |

| . | 0.4724 | 12.0000 | . | 1.5748 | 40.0000 | 8 | 8.0000 | 203.2000 |

| 31/64 | 0.4844 | 12.3031 | . | 1.6142 | 41.0000 | . | 9.8425 | 250.0000 |

| . | 0.4921 | 12.5000 | . | 1.6535 | 42.0000 | 10 | 10.0000 | 254.0000 |

| 1/2 | 0.5000 | 12.7000 | . | 1.6929 | 43.0000 | 20 | 20.0000 | 508.0000 |

| . | 0.5118 | 13.0000 | . | 1.7323 | 44.0000 | 30 | 30.0000 | 762.0000 |

| 33/64 | 0.5156 | 13.0969 | 1 3/4 | 1.7500 | 44.4500 | 40 | 40.0000 | 1016.0000 |

| 17/32 | 0.5313 | 13.4938 | . | 1.7717 | 45.0000 | 60 | 60.0000 | 1524.0000 |

| . | 0.5315 | 13.5000 | . | 1.8110 | 46.0000 | 80 | 80.0000 | 2032.0000 |

| 35/64 | 0.5469 | 13.8906 | . | 1.8504 | 47.0000 | 100 | 100.0000 | 2540.0000 |

Typical Mixing Screw for Single Screw Extruders, 30:1, Maddock Mixer and Pineapple Mixer

![]()

QUICK TIPS FOR PURGING PLASTIC

Chemically enabled Plastic Purging Compounds like XPD8® are

heat activated. To achieve optimum results, you must raise your heats

in the areas that you know problems are likely to occur. Such as: ![]()

Dies ![]()

Areas of Negative Flow ![]()

Sharp Angles in The Flow Path ![]()

Blow Molding Heads

However, in areas that you feel you don't have a problem, do not deviate

from normal heat profiles recommended

![]()

The Feeder Zone in Injection Molders ![]()

Straight Screw and Barrel in Extrusion Systems

By following these guidelines, you will be assured that the chemical

activity of the Purging Compound will be used where it is needed and not

prematurely expended and wasted in areas where it is not necessary.

RBM suggests

that every time you have a prolonged shutdown of your equipment to

employ the amazing abilities of XPD8® High

Performance Plastic Purging Compounds to give you worry free restarts

time after time.

XPD8® Compounds

will not freeze up your screws, will never plug up a die head, and will

guarantee an easy start up after a prolonged shutdown without any

problems at all.

Note: Milabtech LLC is providing this information as a service, and is not responsible for results. If you have any questions, contact the manufacturer below.

Click this link for a video on purging

Call (810) 519-6122 or (810) 516-1700 or (810) 516-1700 for Pricing

14042 Iroquois Woods Dr.

Fenton, Michigan 48430