NEW

Scientific

Mini

3

and 5 layers

Co-Extrusion

Film Blowing Line Type LMF-200

CO-EX

with 3 and 5 Extruders respectively

WITH 16 MM, 30 L/D EXTRUDERS FOR PROCESSING MANY RESIN TYPES AND

ALLOWING OPTIMUM DISPERSION OF ADDITIVE MASTERBATCHEES

Our

new

Mini

LMF-200

CO-EX

film blowing line

is a viable low-cost alternative to our regular co-ex

film blowing lines.

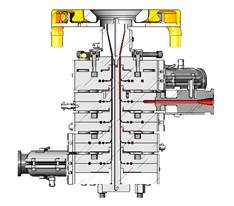

The line has either 3 or 5 extruders of lowboy-type connected to their

respective 3 and 5 layer pancake-type film blowing dies.

The line is also equipped with an oscillating nip-roll as the the

standard haul-off system where the entire film tower including the

wind-up section oscillates

360° back and forth over the die assembly.

Our

new

Mini

LMF-200

CO-EX

film blowing line

is a viable low-cost alternative to our regular co-ex

film blowing lines.

The line has either 3 or 5 extruders of lowboy-type connected to their

respective 3 and 5 layer pancake-type film blowing dies.

The line is also equipped with an oscillating nip-roll as the the

standard haul-off system where the entire film tower including the

wind-up section oscillates

360° back and forth over the die assembly.

THE LINE FEATURES:

¨

Compact design taking up a minimum of floor space of only 1.9 x 1 m.

(6.2 x 3.3 ft) plus electric cabinet of 1.1 x 0.4 m ( 3.6x1.3 ft )

¨

The entire line is mounted on a sturdy steel podium eliminating the need

to secure the extruders and tower to the floor. The steel platform

containing all major supply cables, hoses, and air ducts gives a very

clean appearance with very few visible connections to the extruders and

the tower.

¨

Tower assembly is mounted on

bearing rails, enabling easy access to the die and air ring.

¨

Lowboy

type extruders are aligned to the low height of the die for convenient

assembly and operation.

¨

Modular pancake die assembly of custom design in consultation with our

Canadian expert designer for optimum co-ex

film applications using your specific

types of polymer.

¨

Air ring for

optimum cooling efficiency.

¨

Easily adjustable stabilizing cage with Teflon rollers for various film

bubble diameters.

¨

Compact oscillating film tower which greatly minimizes

the effects of film gauge variations

for quality film rolls.

¨

Surface wind-up station with air shafts for easy changeover of rolls.

¨

The machines are designed to occupy minimum space and to optimize the

workspace.

¨

Fully computerized

LMF-200

CO-EX

Compact Film Blowing Tower

Tower Structure

·

Assembled on a heavy-duty

steel support frame fixed on a steel base floor. The standard height

from floor to nip-rolls is only 1.9 meter (6.2 ft) making it very easy

for operator to thread the film

·

Height from die lip to Nip-Rolls 104 cm (3.4 ft)

·

The nip roll width is 200 mm with 180 mm maximum film lay-flat width.

·

Equipped with four guide rollers down stream to maintain suitable

tension before windup.

Air Ring and Blower

§

High

efficiency cooling ring with optimum cooling efficiency and high

stability of the film bubble.

High

efficiency cooling ring with optimum cooling efficiency and high

stability of the film bubble.

§

Supplied with a streamlined air distribution manifold.

§

The cooling air is supplied from a variable speed 0.37

kW turbo blower. The RPM of the blower is

controlled with a turning knob on the tower’s control panel and is

regulated by an AC frequency inverter.

§

The fan speed regulation optimizes the cooling of the film.

Streamlined air distribution nozzles ensure an even airflow all

around the cooling ring.

§

Equipped with analogue air pressure and air temperature meter

§

Four flexible hoses connected to the air ring from the distribution

manifold and blower.

Bubble Stabilizing Cage

·

Four levels of cage arms covered with free-rotating Teflon rollers.

·

Easily

adjustable cage size via a

knob for various film bubble diameters where all Teflon roller arms are

moved synchronously.

Easily

adjustable cage size via a

knob for various film bubble diameters where all Teflon roller arms are

moved synchronously.

Tower

with Collapsing Frame and Haul-off

Nip Rolls

Tower

with Collapsing Frame and Haul-off

Nip Rolls

·

Collapsing frame

consists of polished teak wood slats for smooth guiding of delicate

films.

·

Pneumatically-operated

nip rolls

consisting of a wear-resistant

rubber idle lay-on

roll and a

hard-chromed

surface polished roll driven by a heavy-duty,

infinitely-variable-speed

servo motor drive and inverter.

Surface Winder

·

Standard surface wind-up

system

with rubber lay-on

roll and a polishing roll driven by an independent variable-speed

servo motor drive with constant torque for quality film roll winding.

·

Separate

3

inch

free-rolling,

windup air shaft

mounted on the windup rack for easier bobbin handling

(Customer

is provided with one unit.

Additional air shafts are available to order).

Equipped as standard with Compact 360° Oscillating Tower

for effective minimizing of film gauge variance

·

The

newly introduced

oscillating tower frame

has a rotary base mounted on a gear assembly driven by a servo drive

motor for a full 360° oscillation of

the stabilizing cage, collapsing frame and the haul-off

nip-rolls to counteract

and effectively minimize film gauge variance occurring during the film

blowing. For high-quality film winding with a uniform film roll geometry.

The

newly introduced

oscillating tower frame

has a rotary base mounted on a gear assembly driven by a servo drive

motor for a full 360° oscillation of

the stabilizing cage, collapsing frame and the haul-off

nip-rolls to counteract

and effectively minimize film gauge variance occurring during the film

blowing. For high-quality film winding with a uniform film roll geometry.

·

Simple and smart design uses few moving parts, allowing for easier

handling and maintenance.

Multilayer Film Blowing Pancake Die Assembly for CO-EX

Lines

LPD20-40

Die Design

¨

Modular die assembly with 5 pancake die layers, each made of high grade

tool steel and with low-friction

nickel coating and mirror polished channels and mandrels for optimum

melt flow performance.

Features annular die lip diameter sizes ranging from 20 to 40 mm with

easily changeable mandrels suitable for use with

Labtech’s

16 mm single screw extruders.

(Different

die lip rings and mandrels sizes supplied according to customer’s

specific resin types and layer configuration)

¨

We custom design our dies in full conformity to customers’ requirements

with consultation from Dr.

John Perdikoulias of Compuplas, Canada.

This ensures a die design with optimal rheological performance and

compatibility in accordance to all polymers specified by the customer.

The binary distribution and spiral flow channels leading to the mandrel

have been analyzed using the latest software analysis technology to

optimize the flow properties throughout the entire die and achieving a

very efficient, uniform distribution of the melt in each layer.

Optimized Melt Flow Channels

·

Melt

from the feed ports, coming from the extruders, flows into the outer

edge channel of the pancake die, which is then repeatedly divided into

binary flow distribution channels

(2,

4, 8 and so on)

ending with multiple channels running around the die for optimum

flow distribution.

As they flow near the centre, they enter a spiral flow pattern before

converging back together into a single annular area with uniform volume

and distribution around the die mandrel, which greatly improves the

uniformity and consistency of each layer thickness.

Melt

from the feed ports, coming from the extruders, flows into the outer

edge channel of the pancake die, which is then repeatedly divided into

binary flow distribution channels

(2,

4, 8 and so on)

ending with multiple channels running around the die for optimum

flow distribution.

As they flow near the centre, they enter a spiral flow pattern before

converging back together into a single annular area with uniform volume

and distribution around the die mandrel, which greatly improves the

uniformity and consistency of each layer thickness.

·

The melt then flows upwards combined with the other layers in a laminar

fashion along the mandrel towards the die exit where the film is

externally cooled and blown into a bubble with uniform wall thickness.

The die is also equipped with centering bolts for adjusting the die

centre position relative to the mandrel for fine tuning the bubble’s

thickness uniformity.

Co-Extrusion

Die Assembly

Co-Extrusion

Die Assembly

¨

The 3 or 5 die layers are supplied for the LMF-200

CO-EX

line.

Each layer has feed ports into which high-pressure,

heated adaptors are attached for connecting to designated extruders.

¨

The adaptors are equipped with heating bands and thermocouples

(fitted

in the mid-section)

for monitoring and regulating temperatures up to 300°C.

¨

Individual thermocouples and heater bands for each die layer (module)

allows for individual monitoring and temperature control up to 300°C.

Each layer is partially isolated from the next layer to minimize heat

transfer from one layer to another.

¨

All temperature-controlled

parts are monitored and set on the LCC computerized touch screen control

panel.

Thermocouples and heater band cables are organized and connected to a

separate signal control cabinet that comes with the assembly.

|

Price in US$ for die core mandrel |

|

|

Die type |

Die LPD20-40 |

|

Suitable for COEX Film Tower type : |

LMF-200 |

|

Converting form 3 layers to 1 layer |

690 |

|

Converting form 5 layers to 1 layer |

920 |

|

Converting form 5 layers to 3 layers |

860 |

30 L/D

Mini

Single-Screw

Extruders

with 16 mm Diameter

Type LME16-30/C-HA

Mini

non-vented

extruders for processing all available types of film blowing resins

General Design

·

New

“Single

Pillar”

versions where the barrel and motor drive is mounted on a single heavy-duty

pillar support.

The lowboy cantilever barrel design conveniently fits into the lower

pancake layer (module) positions for more convenient assembly of the

heated pipes to the die.

·

Narrow and streamlined body

minimizes space consumption

for easy maintenance.

·

Heavy-duty,

compact base for securing the fixture to the base platform.

·

C-clamp

on the terminal flange allows for quick and secure connection to adaptor

pipes and die layers

·

Extruder can easily be swung to the side for removal of the screw. And

for purging

·

Internal and external steel parts coated with heavy duty epoxy paint.

Barrel

and Screw

Barrel

and Screw

·

Barrel and screw

made of high-grade

quality steel with

nitride hardened surface

·

The 16 mm screws are with an L/D

of 30

·

Full stainless steel cover over the barrel with air venting grilles on

th

e sides.

Barrel Heating and Cooling System

·

2 thermo-regulated

barrel zones for the 16 mm diameter extruder.

·

Each zone with high wattage heaters and efficient cooling fan.

·

Standard maximum heating temperature of 300°C and an optional 400°C max

for high-heat version.

·

Water-cooled

feed section to prevent premature melting of resins

Infinitely Variable-Speed

Servo Motor Drives on all extruders

¨

High performance vector drive motor with high torque through the entire

speed range for precise feed-rate

of melt to the die layer resulting in a high layer thickness precision

and better tolerances even at low feed-rates.

The servo drive motor allows for infinitely variable speed adjustments

from 0 up to the 150 RPM max ensuring a very even resin flow at low RPM

which is particularly important to obtain very thin film layers.

¨

Screw shaft driven by a reducer gearbox mounted directly on a heavy-duty

thrust bearing housing

Touch Screen Control Interface

¨

The entire line with extruders and optional gravimetric feeders as well

as die layers and downstream equipment is fully computerized and

controlled on a large touch screen.

The touch screen is mounted on a free standing cabinet.

Hopper

¨

Polished stainless steel hopper with lid mounted on a slide valve plate.

Technical Data for Mini

Single-Screw Extruders

Maximum Output at 150 RPM with our 16 mm Single-Screw Extruder

LE 16-30 (kg/hr)

|

POLYMER TYPE

(Regular pellets) |

HDPE |

PET |

PMMA |

NYLON |

GPPS |

ABS |

PP |

EVOH |

LLDPE |

LDPE |

PLA |

PC |

|

Maximum Output

(kg/hr) |

1.7 |

2.7 |

2.7 |

2.1 |

2.4 |

2.6 |

1.8 |

2.7 |

1.9 |

2.0 |

2.5 |

2.7 |

|

% of Maximum Motor Power |

80 |

61 |

60 |

30 |

38 |

58 |

57 |

64 |

90 |

65 |

80 |

91 |

Computerized

Central Control Unit

·

Features

a

12 inch

LCD touch screen control panel

mounted on a sturdy,

fixed control

stand with a sleek design and an angled display for comfortable viewing

of line parameters on

Labtech’s

fully computerized control interface for the

LMF-200

CO-EX

Features

a

12 inch

LCD touch screen control panel

mounted on a sturdy,

fixed control

stand with a sleek design and an angled display for comfortable viewing

of line parameters on

Labtech’s

fully computerized control interface for the

LMF-200

CO-EX

·

PLC with large processing capacity allows interface connection with

multiple extruders, blowers, and the die assembly.

Supplied complete and wired to all components of the film blowing line.

·

Temperature control and monitoring

of all thermoregulated zones in the line.

·

Speed controls

for the extruders, nip rolls (haul-off), and blower units.

¨

Supports

various drive speed control modes for the extruders.

Supports

various drive speed control modes for the extruders.

¨

Sync Co-Ex:

Master-slave

extruder synchronized control.

¨

LIW

(loss-in-weight)

auto-override

of drive speed for constant feed rate

(only

applicable for extruders equipped with the optional gravimetric

hopper-feeder system).

¨

Sync LF:

auto-sync

tower haul-off

and pull rolls with extruder drive speeds.

·

Generation of real-time

graph trends

of processing temperatures and speeds for comprehensive parameter

monitoring and quality control.

-

Integrated alarm system and real-time

system diagnostics

with user notifications for easier troubleshooting of the line.

-

Save and load pre-set

parameters on internal and external memory with the

RECIPE feature.

-

Secure supervisory control with

Authorized User Control Protection

feature which restricts access to advanced settings of the line.

Gravimetric Hopper feeder controls are incorporated on same touch screen

as the central control unit

The weighing hoppers are controlled on the main LCD color touch screen

panel with easy to read and understand graphics.

All feeding parameters for the weighing

hopper units are easily keyed in on the panel where you also have

screens showing real time data, etc.

OPTION:

Weighing

Hopper Feeder with Computerized Control System

for precise control of individual layer thickness and distribution to

the die assembly

In order to achieve a precise control of the layer thickness in co-extrusion

lines, each layer needs to be fed with a precise amount of resin.

This can best be achieved by using our weighing hopper system.

Our very favourable priced and very accurate system features our

computerized

loss-in-weight

(LIW)

type weighing hopper

system, where each extruder hopper will deliver a user-set

amount of resin

(in

weight units per minute),

in which the feed rate is simply keyed into the touch screen central

control unit.

The central control unit has a setup screen, where you can set all the

required feed rates for each individual weighing hopper as well as the

layer ratio, thickness and even the total system output

(kg/hr).

Density values for the various resins can be inputted to enhance

automatic layer ratio control.

The control panel has a multitude of screens with various functions and

a graphic illustrations of the extrusion control trends.

The system is connected in a closed loop system with the extruder drive

speed control.

Thus, when keying in the exact feed rate on the central control panel

for a specific extruder, the weighing hopper on the extruder will sense

the amount being fed to it, and the controller automatically regulates

the screw RPM so that it feeds exactly the amount of weight units per

minute as previously set on the panel.

If the control system is linked with the LCC Central Control Unit as a

sub-system,

the

LIW

speed control mode

is integrated on the LCC control panel where it can be enabled and

disabled.

Weighing Hopper Features

·

The weighing hopper incorporates a precision load cell for accurate

sensing of the hopper weight.

·

Above the weighing hopper is a stainless-steel

refill hopper mounted on top with a pneumatic slide gate which will open

automatically to refill the feeder tank whenever the material level is

low.

·

The weighing hopper has a

volumetric capacity of 2.2 liters and a

material weight capacity of 1.5

kg of pellets.

·

The refill hopper has the same volume as our regular extruder hoppers

and is also equipped with a sight mirror for easy viewing of the resin

level.

·

The maximum feed rate of the weighing hopper is 1 kg/hr.