| Extruders | Roll Mills | Presses | High Speed Mixers | Filter Test | Blow Molding | Pelletizers | Co-Ex Blown Film | Co-Ex Cast Film | Ultra Micro Extruders | Contact us for quote |

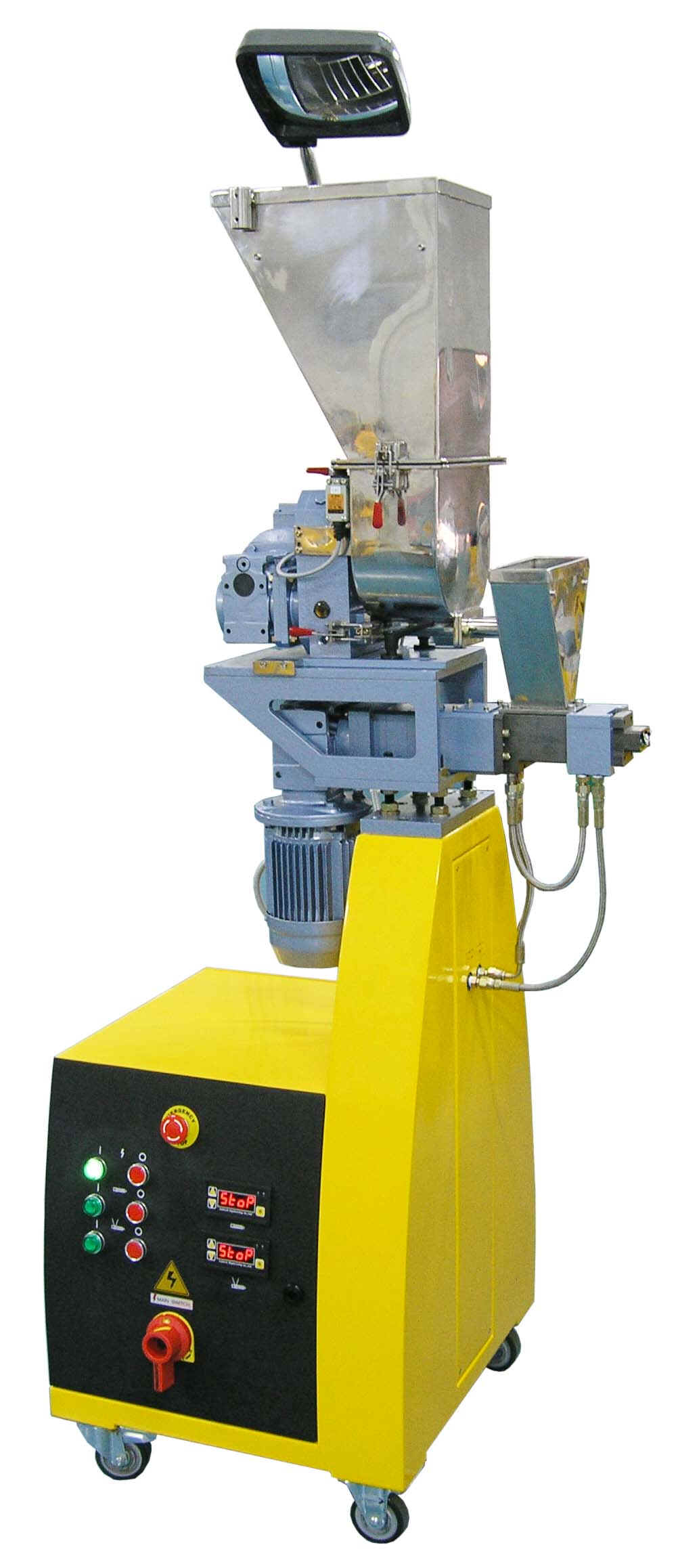

The twin screw extruders are supplied as standard complete with a stainless steel volumetric hopper feeder with a “spiral type” screw and with a stirring arm (agitator) above the feeding screw. The hopper feeder can optionally also be equipped with twin screws.

Twin Screw Extruder Feeder Selections

Additional hopper feeder, to be placed next to existing hopper feeder in a 90 degree angle feeding down to extruders in feed section. The hopper feeder can also be positioned to feed into another barrel opening from the top. Further the hopper feeder can be used to feed into the hopper of the side feeder as shown on right picture. With this the hopper feeder will determine the feed rate to the side feeder which enables better precision and easier calibration. Price includes infinite variable speed drive with AC frequency

Shown here with Optional side stand for feeder.

Twin screw side feeder type LSF16 with screw length of 10 D and water cooled barrel. The screws used here are the same as the feed screw elements used in main twin extruder and they are mounted on same size hexagonal shaft. Complete with infinite variable speed AC servo drive, The side feeder is mounted on a practical swing arm for easy removal The speed regulation will be controlled from extruder panel on a digital RPM instrument with scroll buttons or, if the extruder is equipped with computer controls, it will have all controls on the touch screen. Side feeder is supplied complete with barrel side opening and plug.

Loss in Weight Gravimetric Feeders

Whenever there is a need for a precise mixing and dosing of powders and pellet, a gravimetric feeding system is essential. The standard volumetric feeder supplied with our twin screw extruders is excellent when you feed a pre-mixed blend into the main inlet of the extruder because here all the components in the compound have been precisely weighed before the pre-mixing was done.

These LIW feeders can be mounted on the optional side stand shown on the feeder above.

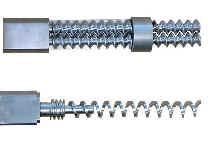

The Gravimetric Feeders are equipped with a practical screw drive system, where the screws are driven by a timing belt and where it is very easy to change over from one screw type to another, be it single or twin screws. Thus the same feeder can be used for feeding all kind of materials, be it in pellet or powder forms, by just changing the screw assembly as shown here to the left.

The central control panel shown here is equipped with a large LCD screen and a multitude of touch pad keys where all feed data can easily be programmed to the system. The LCD screen is clearly visible from a distance to give instant information to the operator. The panel and PLC holds a multitude of pre-programmed formulations

The gravimetric feeders can be connected together and the feed rate on each unit can be set precisely on the central control panel so that they all follow each other synchronously. Usual one feeder will serve as the master feeder, connected to the twins main in feed zone and then additional feeders can be added to feed down into the main in feed zones as well as into designated side feeders. These “slave” feeders can each easily be set at a specific feed rate so that the all feed in a very precise percentage to whatever is fed from the master feeder.

frequency combine for superb self-priming and degassing properties The pump is programmable up to 360 strokes per minute with infinite adjustable pump volume from 0 to 2,280 ml per hour (0 to 38 ml/minute).

The pump delivers a high pressure of max 150 psi which is more than sufficient to inject the liquid into the extruder barrel in any desired zone.

The programmable pump allows for programming of the pump speed and input

settings using the alphanumeric display and four-button keypad. Control

modules are detachable for easy access and remote capabilities.

Pumps have digitally adjustable speed control and manual adjustable

stroke length (1800:1 turndown). External input control is offered via a

pulse input or analog signal which is connected to the extruder touch

screen control.

Twin screw gravimetric feeder system with Siemens Touch Screen controller. Unit features high resolution weighing system, round bottom hopper with conical agitator, sealed drive motor.

Call (810) 516-1700 for Pricing

14042 Iroquois Woods Dr.

Fenton, Michigan 48430