| |

Labtech Engineering is the proud manufacturer of durable, precise and

innovative laboratory equipment for the plastics industry. Labtech

builds equipment to the highest quality standards and in strict

conformity to CE and all other world safety norms. Our products include

Two-Roll Mills, Rubber Mills, Hydraulic and Electric Presses, Single Screw and Twin

Screw extruders, Chill Roll Film and Sheet Casting Lines, Blown Film

Lines, Filter Test, Mixers, and more…

Under Swedish management, Labtech Engineering manufactures in

Bangkok, Thailand and is exporting to the Canadian, and United States market.

This 9 layer co-extrusion blown film line was designed for a customer in

the MidWest USA to allow the operator extra work space around the die,

and for a low ceiling height.

Mini Chill roll cast film line with

16mm extruder for maximum color dispersion.

150mm chill

roll width. |

|

Mini 5 layer co-extrusion line

|

|

|

|

|

|

|

|

|

|

Video of 5 Layer Compact Blown Film Line with oscillating nip

rolls: https://www.youtube.com/watch?v=V9ebCaxTZ5Q&t=37s |

24:1 L/D, 12mm/8mm conical screw accepts 1.5mm X 1.5mm pellets, perfect

for Universities.

Click Here to see Video.

OUR

PRODUCT LINE - LABORATORY EQUIPMENT

_____ _____

130 meters/minute

with outstanding reel geometry, to be shown at the 2022 K Show

Totally new advanced design high speed winder with no "birds nests"

Click here to view video of previous line running!!!

_____________________________________________________________________________________________________________________________

|

Laboratory Blown Film Lines:

12.5mm, 20mm, 25mm, 30mm, 40mm, 45mm, 60mm, all 30:1 L/D extruders.

Blown film lines for film lay-flat widths of up to 550 mm.

Include features such as a twin-channel cooling ring, nip rolls,

variable speed haul-off, slitters and winder. Blown film

die sizes from 20mm to 120mm.

An optional oscillating nip roll is available for the LF-400

blown film line.

Co-extrusion lines for films with up to 9 layers. Large film

tower with twin pillars, modern design enclosure, pneumatic nip

rolls, infinitely variable-speed drive, high-capacity cooling

ring, film wind-up, and freestanding central control cabinet

incorporating all controls for the tower and extruders.

|

|

|

|

|

|

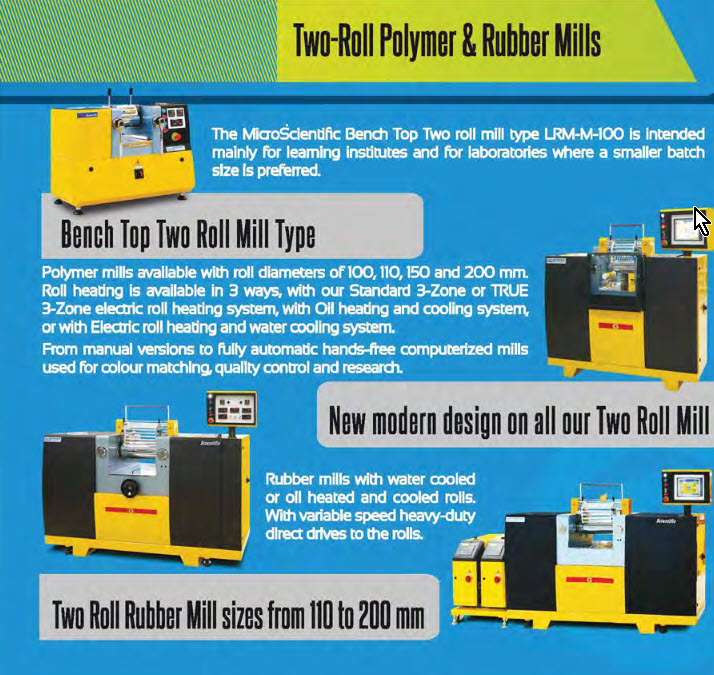

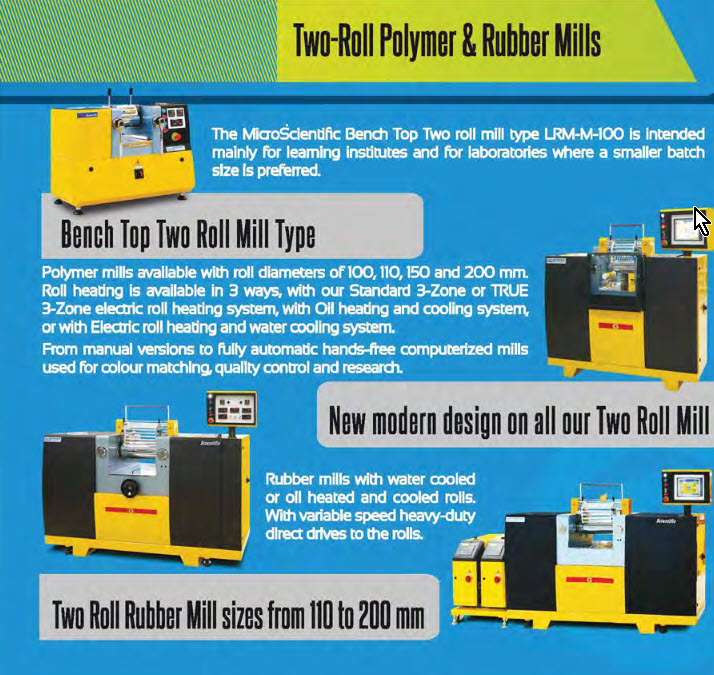

Two

Station Surface Winders and Single or Two Station Constant

Tension Winders

The Constant Tension

Winders are equipped with bobbin free pneumatic expansion shafts

for easy roll removal. Tension for both rolls is

independently adjustable.

|

|

|

Hydraulic & Electric Laboratory Presses:

Hydraulic laboratory presses from 20 to 80 metric tons platen

pressure. A double set of heating and cooling platens are

standard. Available with a fully automatic platen insert cooling

system as well as many platen configurations and control

options.

An all new totally electric 20 ton press - Debuted at the 2012

NPE show in Orlando, Fl. |

|

|

Laboratory Filter Test:

Filter test with and without a gear pump for accurate quality

testing and standardization of masterbatches and compounds.

Standard filter sizes from 15 down to 5 microns. |

| |

|

Laboratory Single Screw Lab

Extruders:

Single screw laboratory extruders

with diameters of 12,5, 20, 25, 30, 40, 45, and 60mm all with an L/D ratio of 30:1. The 20 mm extruder is

available as a table top version. The 25mm and larger extruders are

available both in vented or non-vented versions with plain

screws or equipped with a Maddock mixing section, as well as a

pineapple mixer at the screw tip.

25mm Vented

Extruder

|

|

|

Laboratory High Speed Lab Mixers:

25 and 75 liter pilot plant high-speed mixers with variable

impeller speed, automatic mixing cycles and optional

water-cooled impeller. |

| |

|

N N

All new design 26mm Twin Screw

Extruder

|

Laboratory Co-rotating Twin

Screw Extruders:

Modular co-rotating twin screw extruders have clam-shell barrels

and our unique super hard tool steel barrel inserts. Fully

closed barrels are an option. Machines are available with 12,

16, 20 and 26 mm screw diameters and L/D ratios from 32:1 to

48:1

These twin screw extruders can also be matched up with a gear

pump to our chill roll casting sections, and blown film sections

for development of Bio-polymers and other special film products.

A new 26mm COMBI Co and Counter rotating extruder to compound

PVC compounds also!!

|

Laboratory

High Speed Mixers:

Manual and computerized high-speed mixer with

optional Cooling mixer. Available in sizes from 5 to 75L,

Cooling mixers up to 50L. |

|

Pelletizing Systems:

Strand, (Air or Water

Bath), and Hot Cut air cooled Pelletizing for Laboratories and product

development, small run masterbatch production. Underwater

pelletizing systems. |

All New! Medical Lab Extruder, 12mm Twinscrew, Air Strand

Cooling, Micro Pelletizer |

|

|

|

Laboratory Chill Roll Film and Sheet Casting Lines:

12.5mm, 20mm, 25mm, 30mm, 45mm, 60mm extruders, all 30:1 L/D.

Chill roll film and sheet casting lines are available both as

floor and bench top versions. Flat die widths range from 125 mm

for bench top versions up to 300 mm for floor versions. Dies

have adjustable lips for sheet thickness from 0.3 to 1.5 mm or

film thickness down to 0.01 mm. All three rolls are hard

chromed, mirror polished and cored for water cooling and

heating. Polishing roll is pneumatically operated.

Co-extrusion flat film and sheet lines for up to

9 layers.

Suitable for producing film and sheet with materials such as PE,

PP, PS, ABS, PVC, PET, PC, etc.

Laboratory MDO Units with winder:

Labtech MDO unit

shown with Co-ex Cast Film Extrusion line. A fully

integrated line with either blown film or cast film for product

development. MDO's are available from 350mm wide to 800mm

wide rolls.

NEW!! : 6 Ton Air Clamp

and servo screw Injection

Molding Machine

for Lab Color Sample Plaques, and automated lights out molding

of small parts. Excellent for Universities,

|

|

|

|

Laboratory Bench Top High Speed Mixers:

Bench top 10, 5 and 1.5 liter mini high-speed mixers with

variable speed drive and easily removable mixing bowl.

|

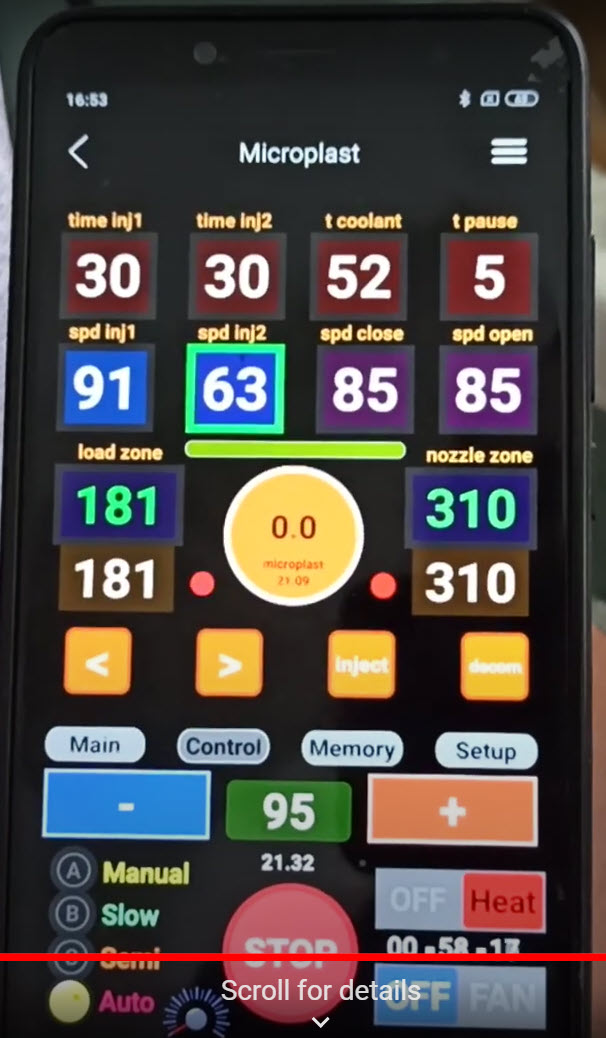

A

small Tabletop One Ton molding machine for molding small parts

up to 5 grams

All

electric, servo motor drives

Runs on 220V single

phase

Only consumes 3 amps power

Simple inexpensive

molds, optional roll around cart

|

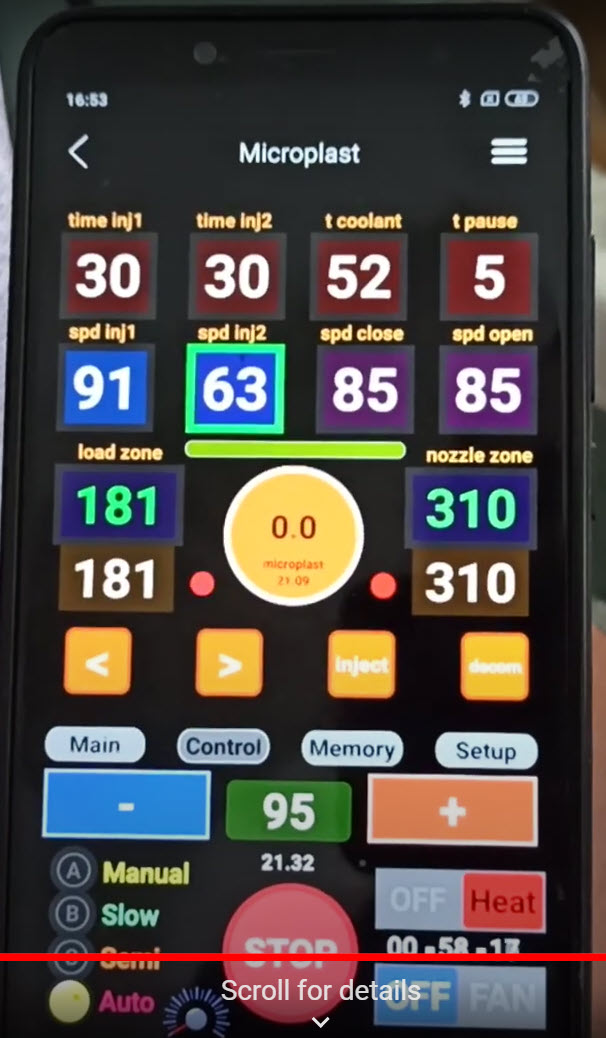

All new!

Microplast 1 ton molder with

bluetooth smart phone control. |

Laboratory Co-Ex Cast and Blown

Film Lines:

12.5mm, 20mm, 25mm, 30mm, 45mm, 60mm co-ex Blown and cast film lines

up to 9 layers.

Blown Film,

(3) 12.5mm

extruders, 3 layer co-ex line

shown in the upper photo. (5) 30mm extruders, oscillating

nip roll, gravimetric layer thickness control, shown in the

lower photo.

|

Single and Co-ex Blow

Molding solutions for your laboratory, and small production

jobs.

|

Laboratory Medical Tubing Lines

25 mm Extruder with 25/1 L/D & bimetallic

barrel and screw

Crosshead Die

10' Cooling Tank with 2' Vacuum Chamber

OD Monitor & Control System

Belt Puller

Traverse Winder |

|

|

|

|

|

Call (440) 812-0132

or (810) 516-1700 for Pricing

|

|

![]()

_____

_____

fault.asp

fault.asp.jpg)